Company Profile

Suzhou Aolide was founded by senior experts and scholars in the printing industry in 2006. Located in Suzhou city, close to Shanghai Port, So the transportation is very convenient.

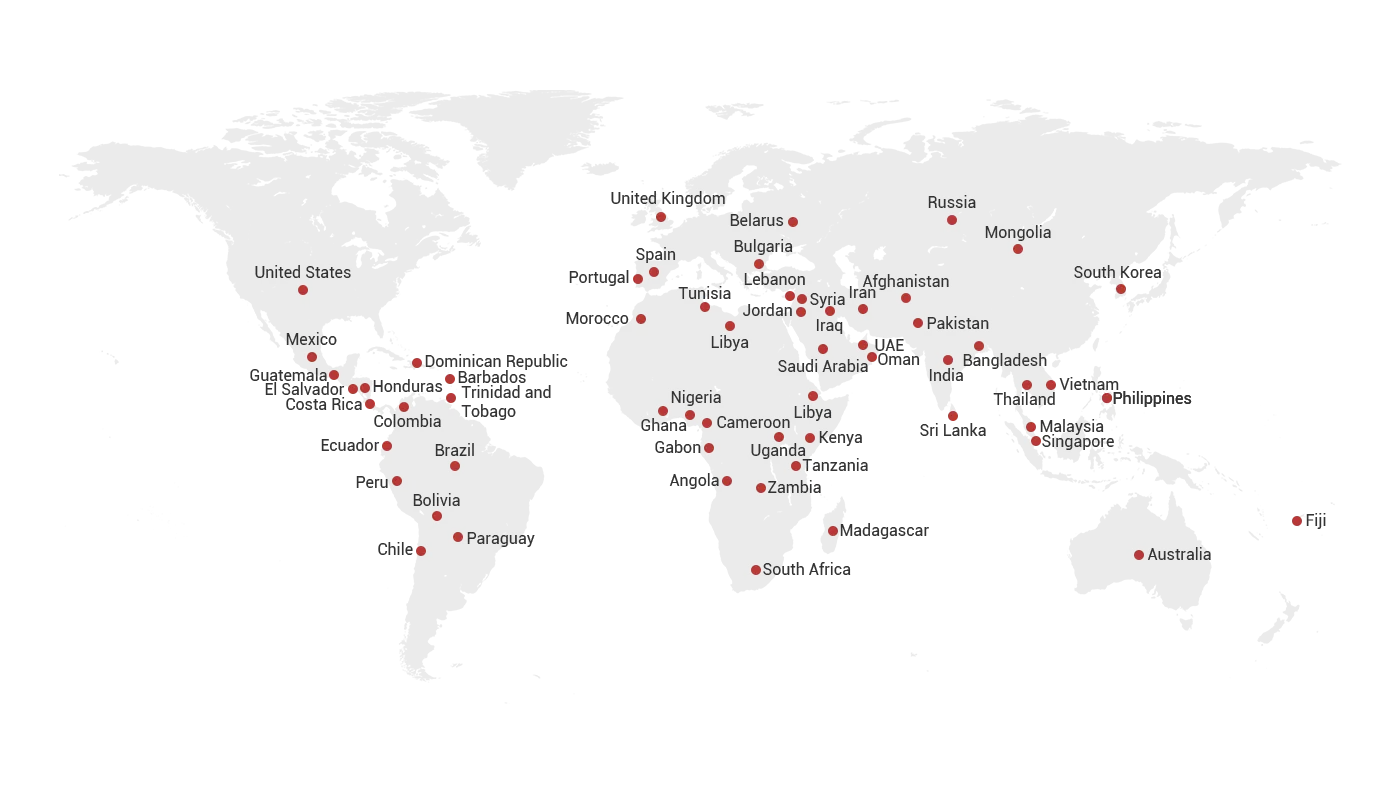

Suzhou Aolide's business covers offset and flexo plate-making project design, technical consultation, Process optimization, production and sales of plate-making equipments and printing materials. Aolide has provided product and service support to partners more than 90 countries.

We adheres to the business philosophy of "customer first, employee first, reputation first", and strives to provide domestic and overseas users with the most cost-effective products and the most satisfactory services.

We adheres to the path of technological innovation and sustainable development, and strives to be a world-class system service provider forthe printing industry.

20+

Established over 20 years ago

90+

Serving customers in over 90 countries and regions

500+

Customer base exceeds 200

95%+

Customer repurchase rate exceeds 50%

20%+

Annual performance growth rate exceeds 20%

advantage

Why Choose AOLIDE

Experienced senior after-sales engineers provide remote or on-site services, and one-stop flexographic printing procurement services cover flexographic printing plate , flexo plate making machines and flexo plate making consumables, etc.

Free production of test plates based on customer test files.

Fast delivery time of 7-15 days, stable product quality, More than 200 world-renowned flexo plate making factories, packaging factories and printing factories cooperate.

Online and offline omni-channel layout.

24-hour customer service, lifetime warranty, senior industry experts, backed by central and state-owned enterprises

PARTNERS

Closed Deals With Customers

Core team

Rich industry experience: The average working experience of core members is over 15 years

Strong technical strength: Owning more than 20 patented technologies

Innovation-driven: R&D investment accounts for more than 8% of revenue

R & D

Research and development strength

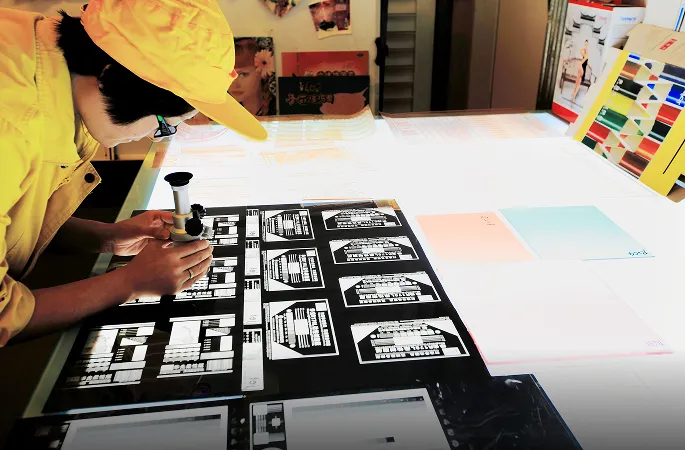

High-Precision Platemaking Technology

Master advanced processes such as laser engraving and digital flexographic plate making to achieve a dot reproduction rate of 1%-98% and support ultra-fine line printing (such as above 150 LPI).

Flexographic Printing Plate Development

We independently develop photosensitive resin plates, water-washable plates and other materials, which have high elasticity, printing durability (up to millions of prints) and environmental protection characteristics.

Application Of Bio-Based Materials

Explore renewable raw materials (such as plant-based resins) to replace traditional petroleum-based materials and promote green printing.

High-Resolution Plate-Making Equipment

Equipped with laser direct engraving machine (such as HDI technology) and 3D printing plate-making equipment to meet the needs of fine printing such as packaging and labels.

Participation in International Standards

Lead or participate in the formulation of printing standards such as ISO 12647 and FOGRA, and lead industry norms.

Circular Economy Model

Promote plate recycling technology and reduce waste emissions

Factory Display

Quality Control

The factory has passed ISO9001 quality system certification and CE certificate

From raw materials, production process to finished product testing, each link has been inspected and tested at least 3 times by different personnel

Certificate

Sustainability

CTP technology is used to reduce film usage and energy consumption by 30%. The solvent recovery machine can recycle waste solvents during plate making, basically achieving zero wastewater discharge. Low-power UV-LED fixed-line system is used to replace traditional pump lamps (energy consumption is reduced by 60% and life is extended by 5 times). Plate recycling and crushing are then re-granulated

Get Started With AOLIDE Now!

We always want to make sure that our customers are getting the best deal, so let us know what you're interested in and we'll get back with a quote

quick links

quick links

contacts

contacts

Tel / WhatsApp

+ 86 158 3829 5140

darrenliu@szaolide.com

get in touch

get in touch